Quality service

The purpose of establishing quality at France Joint is to provide an offer tailored to our customers with controlled processes, while ensuring that the improvement does not add to the general overhead. This is both our objective and yours: Quality products and services at competitive costs, so that tomorrow, France Joint will always be... Your go-to guy.

Certification renewal: guarantee of excellent quality

ISO 9001, IATF 16949, EN/AS 9100, and ISO 14001 certifications are a reflection of the industrial rigour adopted by France Joint. They highlight a constant drive for progress by ensuring quality on all levels. Anticipation, risk prevention, excellent service and continuous improvement are among the key values for which France Joint is known today.

Strong commitment to quality

Quality is France Joint's central focus. It has a systematic approach to the improvement and development of its quality system; it's drive is to better satisfy you. France Joint is committed to:

1 - Adopting the most high-performing methodologies for:

Managing developments and processes

(PPAP, R&R, SPC, IMDS,...)

Ensuring the traceability and conformity of our products

(configuration management, conformity certifications, mastering stock availability)

Monitoring each manufacturing stage

2 - Investing in the best technologies for:

Optimising the quality of the finished product

Removing internal waste

Checking the conformity of the product

Reducing the logistics costs

3 - Selecting the most appropriate partners for:

Securing the quality of provisions

Stopping malfunctions

Zero fault through efficient controls

Centred on the observance of "zero fault", France Joint drives its casting, injection, machining and finishing productions through guidelines that are governed by systematic self-assessment, and assessment and audits of processes and products.

Characterisation of materials

(rheometer, spectrometer, durometer, etc.)

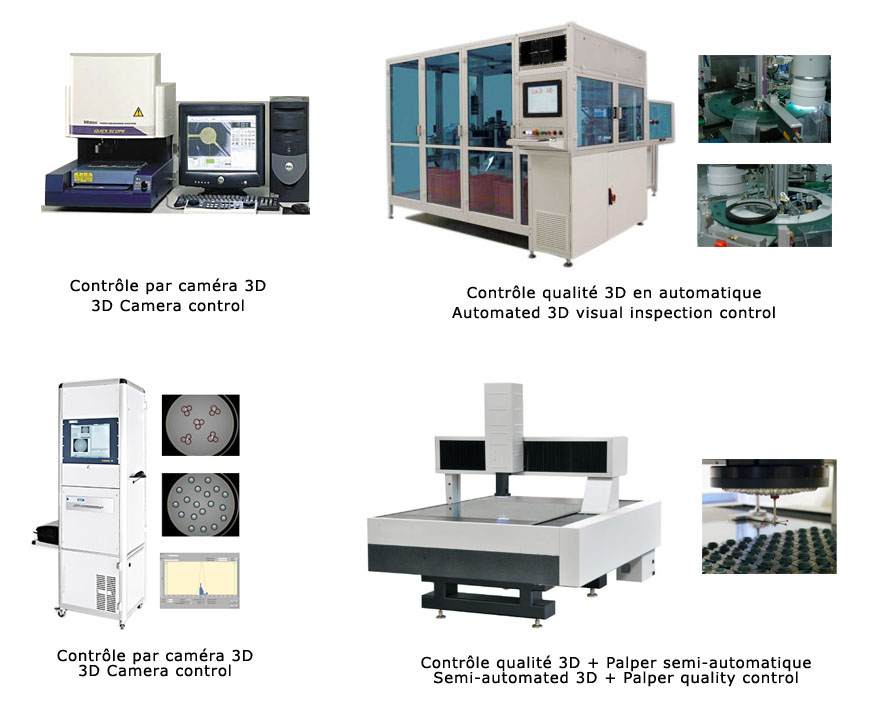

Dimensional controls

(3D measurement machines with optical sensors, profile projectors, diameter tapes, micrometers, depth gauges, probes, callipers, 3D machines with slides, specific gauges, etc.)

Checks for characteristic features

(equipment for automatic unit control using cameras)

Examples of integrated technologies for a 100% satisfaction

(up to 10 parts/seconds, double control table in rotation, control under consraint module, etc...)