Materials

High-performance compounds tailored to your needs

At France Joint, we provide you with a wide range of high-quality materials to meet the requirements of the most varied industrial applications. Our compounds include elastomers, thermoplastics, as well as advanced materials such as TPU (polyurthanes) and PTFE. Each material is specifically designed to guarantee optimal performance in terms of sealing, chemical, thermal and mechanical resistance, while adapting to the most demanding environments.

Whether for standard or critical applications, our expertise allows you to benefit from tailor-made solutions, respecting the strictest international standards (ISO, ASTM, etc.). Discover in the following sections the details of our compounds and their technical characteristics.

Rubber

Thermoplastics

TPU (Polyurethanes)

PTFE

AEROSPACE MATERIALS

Rubber

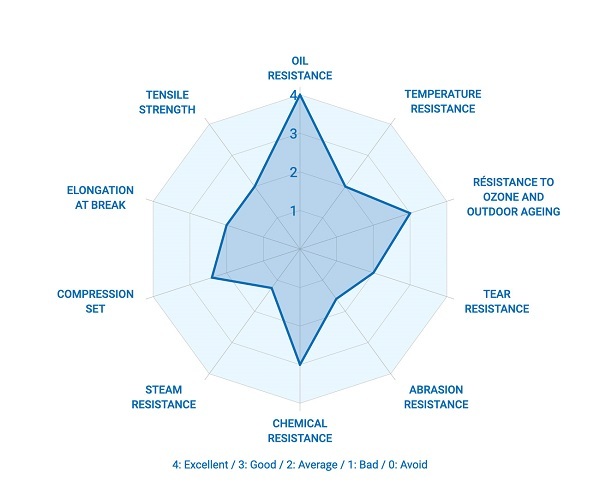

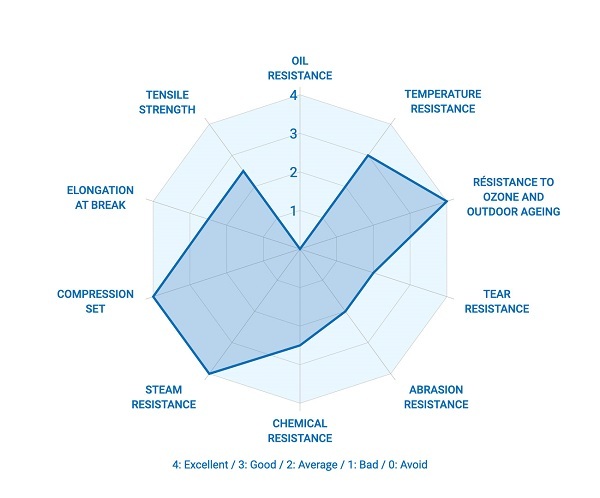

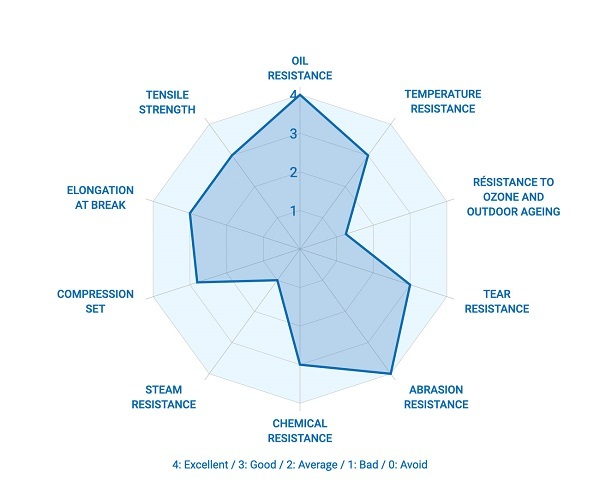

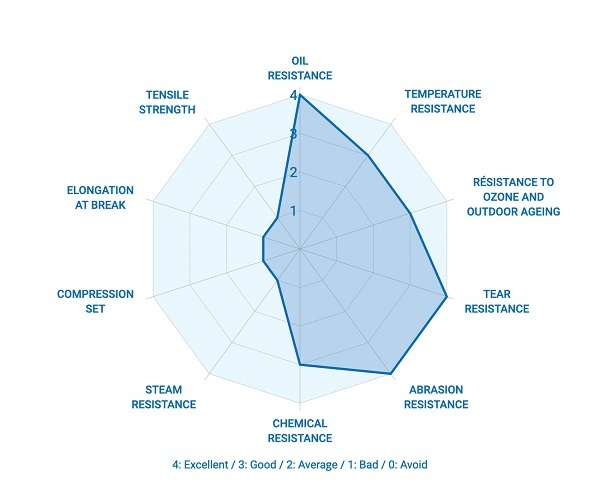

ACM / ACM-HT

Description

ACMs, or polyacrylate rubbers, are synthetic elastomers primarily composed of acrylic acid esters. These materials are widely used for their excellent performance in environments where oil and heat resistance are essential. They are often utilized in formulated blends to meet specific performance and durability requirements.

Temperature

-30 °C (depending on specific formulations)

+150 °C (up to +175 °C for high-performance optimized formulations)

Chemical Compatibility

ACMs are recognized for their excellent resistance to:

Mineral and synthetic oils (including those with additives).

Mineral oil-based hydraulic fluids.

Industrial greases and lubricants.

Aliphatic hydrocarbons.

Ozone and atmospheric aging.

Chemical Incompatibility

ACMs are not suitable for environments exposed to:

Aromatic hydrocarbons (e.g., benzene, toluene) or halogenated hydrocarbons.

Phosphate ester-based fluids (specific hydraulic fluids).

Polar substances such as ketones, esters, or certain powerful solvents.

Hot water or high-temperature steam.

Physical/Mechanical Properties

ACMs exhibit the following characteristics:

Excellent thermal stability: retention of mechanical properties at high temperatures.

Good abrasion resistance and low permanent deformation.

Low flexibility at low temperatures: limits applications in very cold environments.

Good sealing properties: ideal for static and dynamic sealing solutions.

Moderate tensile strength: requires tailored formulations for demanding applications.

Application Examples

At France Joint, ACMs are used in the design and manufacturing of sealing solutions for various industries, including:

Automotive: Seals for gearboxes, transmission systems, and engines; seals for hydraulic fluids.

Mechanical Industry: Static and dynamic seals for machines exposed to high oils and temperatures.

Industrial and Agricultural Vehicles: Sealing for hydraulic and pneumatic systems under extreme conditions.

Energy and Petrochemical: Seals in hydrocarbon-rich environments.

ACMs, with their adaptability and performance in demanding conditions, are a strategic choice for sealing solutions in diverse and critical sectors.

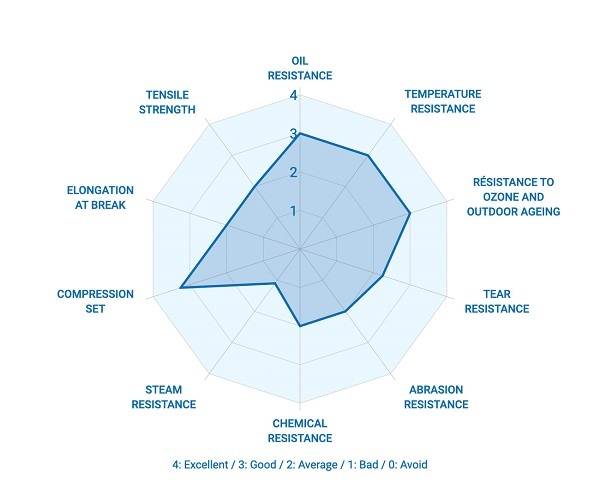

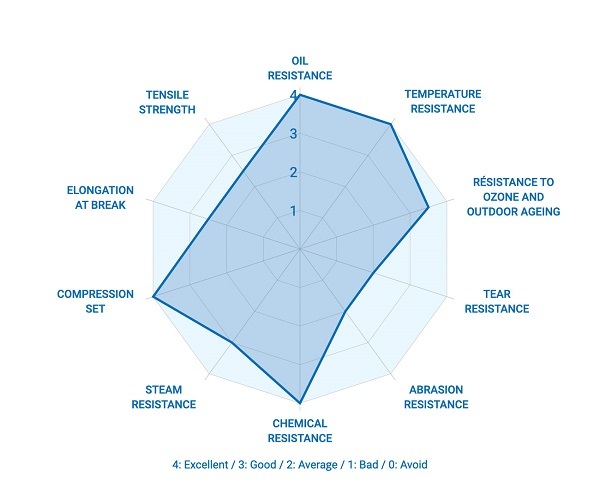

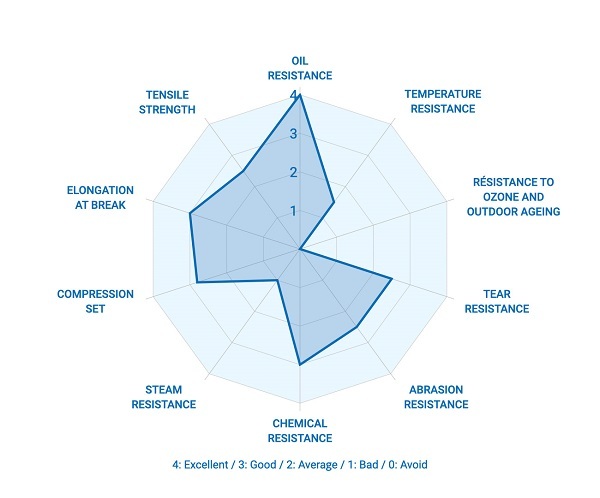

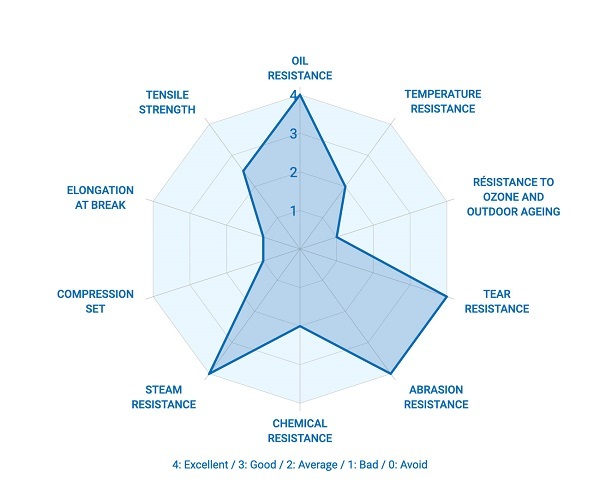

AEM

Description

AEM, or ethylene acrylic elastomers, are copolymers containing ethylene and acrylate monomers. Their chemical structure provides excellent resistance to heat, oils, and ozone, while offering improved low-temperature flexibility compared to similar elastomers. These materials are particularly well-suited for applications requiring reliable performance in demanding environments.

Temperature Range

-40 °C

+150 °C (up to +175 °C for specific high heat-resistant formulations, and up to +200 °C for short-term peak exposure)

Chemical Compatibility

AEM stands out for its excellent resistance to:

Mineral and synthetic oils (with or without additives)

Transmission fluids

Aliphatic hydrocarbons

Ozone and atmospheric agents (weather aging)

Weak acids and diluted basic solutions

Chemical Incompatibility

AEM is less effective against:

Aromatic (e.g., benzene, toluene) and halogenated hydrocarbons

Ketones, esters, and aggressive polar solvents

Hot water and prolonged exposure to high-pressure steam

Phosphate ester-based hydraulic fluids

Physical/Mechanical Properties

AEM exhibits the following characteristics:

Excellent heat and oxidation resistance: Retains mechanical properties even at high temperatures

Good low-temperature flexibility: Advantage over some elastomers such as ACM

Aging resistance: Outstanding durability under climatic conditions

Balanced mechanical properties: Decent tensile and abrasion resistance

Limited permanent deformation: Particularly in static applications

Application Examples

At France Joint, AEM is used in the design and production of seals for a variety of industries, including:

Automotive: Seals for air circuits and oil pans. Sealing for gearboxes and engines exposed to hot oils.

Industrial and agricultural vehicles: Applications in transmission systems and hydraulic circuits. Seals for equipment subjected to severe thermal conditions.

Mechanical industry: Static and dynamic seals for environments exposed to moderate temperatures and industrial oils.

AEM is distinguished by its versatility and ability to meet the high technical requirements of many critical applications, especially those involving combined thermal and chemical stresses.

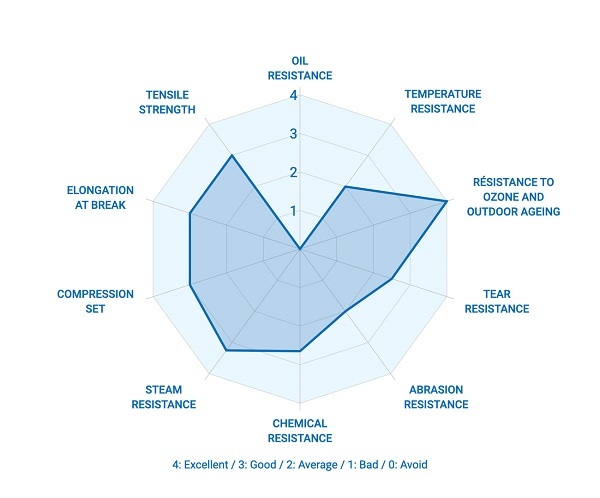

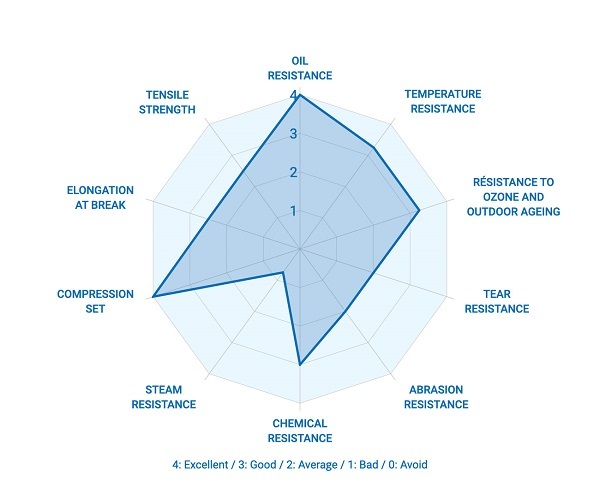

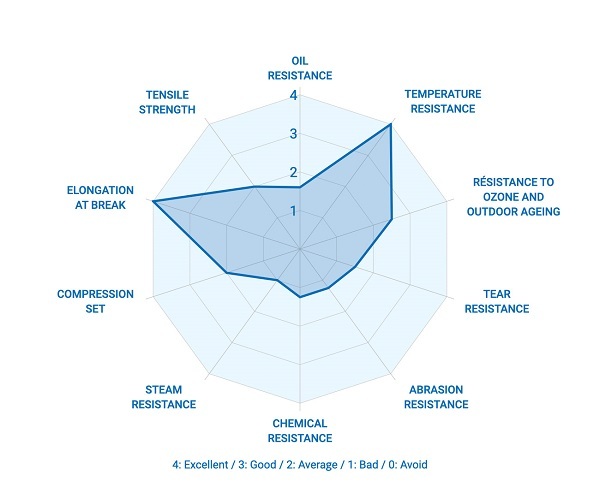

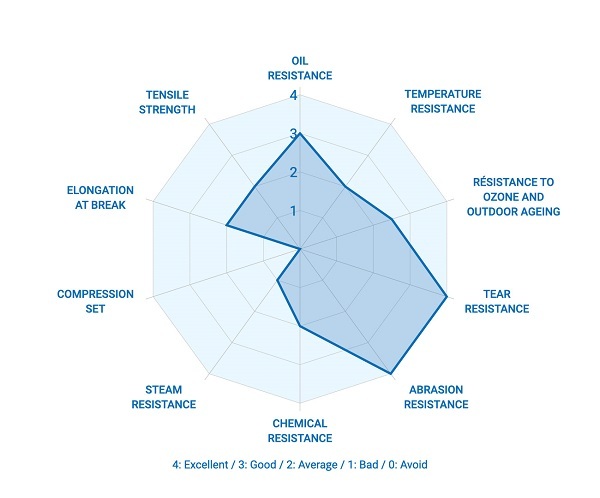

EPDM

Description - Sulfur-Cured EPDM

Sulfur-cured EPDM (Ethylene-Propylene-Diene Monomer) is a synthetic elastomer vulcanized using sulfur. It is notable for its excellent performance in various environments, thanks to its resistance to atmospheric agents and high thermal and chemical stability. This type of vulcanization provides robust mechanical properties.

Temperature Range

-40 °C

+120 °C

Chemical Compatibility

Sulfur-cured EPDM offers excellent compatibility with:

Water and aqueous solutions

Weak acids and diluted bases

Steam up to moderate temperatures

Water-glycol-based hydraulic fluids

Ozone and atmospheric aging

Chemical Incompatibility

These elastomers are not suitable for:

Aliphatic, aromatic, and halogenated hydrocarbons

Mineral and synthetic oils

Phosphate ester-based fluids

Physical/Mechanical Properties

High aging resistance: UV, ozone, and weathering agents

Good thermal stability: Ideal for medium-temperature environments

Low oil resistance: Limits usage in applications involving aggressive fluids

Excellent elasticity: Suitable for dynamic applications

Application Examples

Automotive Industry: Seals for water and cooling circuits (except where sulfur is prohibited due to oxidation concerns)

Building and Construction: Seals for windows and facades

General Industrial Applications: Sealing in environments exposed to water, weathering, and mild chemicals

Description - Peroxide-Cured EPDM

Peroxide-cured EPDM is a synthetic elastomer vulcanized using peroxides. This process provides superior thermal and chemical resistance compared to sulfur-cured EPDM, making it suitable for more demanding environments.

Temperature Range

-45 °C

+150 °C

Chemical Compatibility

Peroxide-cured EPDM is resistant to:

Hot water and steam

Weak acids and diluted basic solutions

Gases such as CO2 (R744) and hydrogen

Water-glycol-based hydraulic fluids

Ozone, UV, and atmospheric agents

Chemical Incompatibility

Peroxide-cured EPDM is not suitable for:

Aromatic, aliphatic, and halogenated hydrocarbons

Mineral and synthetic oils

Phosphate ester-based fluids

Physical/Mechanical Properties

Excellent thermal stability: Suitable for high-temperature applications

Enhanced chemical resistance: Particularly against aggressive fluids such as CO2 and hydrogen

Good resistance to RGD (Rapid Gas Decompression): Ideal for high-pressure environments with special formulations

Fire resistance: Can be formulated to meet UL94HB or UL94V0 standards

Application Examples

Automotive Industry: Seals for applications involving CO2 (R744) and hydrogen, as well as brake system seals

Energy and Oil Industry: Sealing in high-pressure environments with RGD

HVAC Applications: Seals for air conditioning systems using aggressive fluids

Sulfur-cured and peroxide-cured EPDM are distinguished by their adaptability to various industrial environments. Specific formulations ensure compliance with stringent regulatory and technical requirements, particularly regarding chemical, thermal, and mechanical resistance.

Sulfur cured EPDM

Peroxyde cured EPDM

FFKM

Description

FFKM (Perfluoroelastomers) are highly fluorinated elastomers, regarded as the most advanced materials for chemical and thermal resistance. They combine the properties of PTFE (polytetrafluoroethylene) with the elasticity of rubber. Their unique composition allows them to be used in extremely demanding environments.

Temperature Range

-10 °C (depending on the formulation)

+320 °C

Chemical Compatibility

FFKM exhibits exceptional resistance to:

Aggressive chemicals, including strong acids (e.g., sulfuric acid, nitric acid)

Organic solvents (ketones, esters, halogenated hydrocarbons)

Aromatic and aliphatic hydrocarbons

High-pressure gases and fluids

Ozone, UV, and atmospheric aging

Chemical Incompatibility

FFKM has few limitations, but precautions should be taken in the following cases:

Cryogenic environments with temperatures below their minimum operating range

Complex fluid mixtures or extreme conditions requiring specific formulations

Physical/Mechanical Properties

Universal chemical resistance: Compatible with almost all chemicals

High thermal stability: Ideal for applications at extreme temperatures

Exceptional RGD (Rapid Gas Decompression) resistance: Suitable for high-pressure environments with rapid variations

Low compression set: Maintains elastic properties even after repeated thermal cycles

Application Examples

Oil and Gas Industry: Seals for equipment exposed to high pressures and corrosive environments

Chemical Industry: Sealing in facilities handling acids, solvents, and aggressive fluids

Aerospace and Space Industry: Seals for critical systems requiring maximum reliability under extreme thermal and chemical conditions

Semiconductors: Applications in manufacturing environments requiring maximum purity and chemical resistance

Hydrogen Applications: Seals for high-pressure systems in hydrogen energy applications

FFKM represents the pinnacle of performance for sealing solutions in the most demanding environments. Their exceptional resistance to temperature, chemicals, and rapid decompression makes them a strategic choice for critical applications.

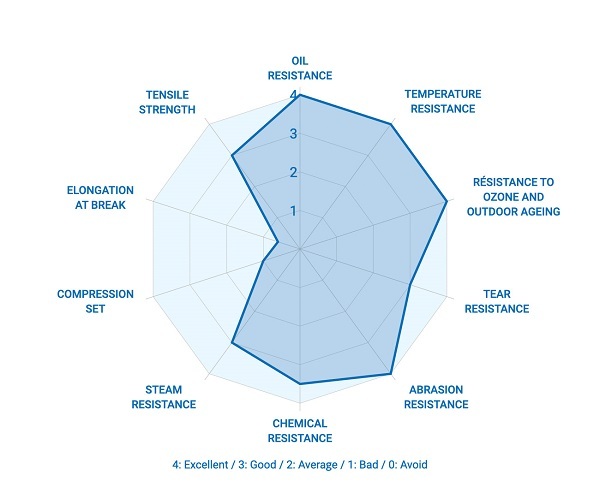

FKM / FPM

Description - Bisphenol-Cured FKM

Bisphenol-cured FKM (fluoroelastomers) are synthetic elastomers based on fluoropolymers. Known for their excellent chemical and thermal resistance, they also exhibit strong mechanical properties. Bisphenol curing is a standard process, providing a good balance between performance and cost for industrial applications. They are free from PFHxA and PFHxS.

Temperature Range

-20 °C

+200 °C (up to +230 °C for specific formulations)

Chemical Compatibility

Bisphenol-cured FKM offers excellent resistance to:

Aliphatic and aromatic hydrocarbons

Mineral and synthetic oils and lubricants

Weak acids and diluted bases

High-pressure gases and fluids such as CO2 (R744)

Ozone, UV, and atmospheric agents

Chemical Incompatibility

Bisphenol-cured FKM is less effective against:

Phosphate ester-based hydraulic fluids

Ketones, amines, and aggressive polar solvents

Prolonged exposure to hot water and steam at high temperatures

Physical/Mechanical Properties

Excellent thermal and chemical resistance: Suitable for many industrial environments

Good mechanical performance: Adequate tensile strength and abrasion resistance

Low permeability: Enhanced performance for gas sealing

Limited suitability for aqueous environments: Degradation accelerates in the presence of hot water or steam

Application Examples

Automotive Industry: Seals for engines, gearboxes, and oil circuits

Petrochemical and Energy Sectors: Sealing in pipelines and equipment exposed to hydrocarbons

HVAC Applications: Seals for refrigerants and CO2 (R744)

General Industrial Applications: Sealing in complex chemical environments

Description - Peroxide-Cured FKM

Peroxide-cured FKM are fluoroelastomers vulcanized using peroxides. This curing method enhances their chemical and thermal resistance, making them suitable for harsh environments. New-generation formulations exclude PFHxA (perfluorohexanoic acid) and PFHxS (perfluorohexane sulfonate), ensuring compliance with strict environmental regulations.

Temperature Range

-25 °C (down to -40 °C for certain formulations)

+200 °C (up to +250 °C for specific grades)

Chemical Compatibility

Peroxide-cured FKM is renowned for its resistance to:

Aliphatic, aromatic, and halogenated hydrocarbons

Mineral and synthetic oils (including those with aggressive additives)

Refrigerants such as CO2 (R744) and hydrogen

Aggressive chemicals, organic solvents, and high-pressure gases

Ozone, UV, and atmospheric agents

Chemical Incompatibility

Peroxide-cured FKM has limitations with:

Ketones, amines, and highly polar solvents

Prolonged exposure to hot water and steam at very high temperatures

Physical/Mechanical Properties

Excellent thermal stability: Suitable for high-temperature environments

Enhanced chemical resistance: Ideal for critical applications

Optimal RGD (Rapid Gas Decompression) performance: Perfect for high-pressure environments

New-generation formulations without PFHxA and PFHxS: Increased environmental compliance while maintaining performance

Low compression set: Durable performance even under prolonged stress

Application Examples

Automotive Industry: Seals for CO2 (R744) and hydrogen applications

Petrochemical and Energy Sectors: Sealing in pipelines, valves, and compressors exposed to aggressive fluids

HVAC and Air Conditioning Applications: Seals for modern refrigerants and CO2

Chemical and Pharmaceutical Industry: Equipment handling solvents and corrosive gases

Aerospace and Space Industry: Systems requiring maximum reliability under extreme conditions

Peroxide-cured FKM, particularly next-generation formulations, offer exceptional performance while adhering to environmental standards. They are particularly well-suited for critical applications requiring a combination of chemical, thermal, and mechanical resistance.

FVMQ / FMVQ

Description

FVMQ (Fluorosilicones) are synthetic elastomers derived from silicones, modified with fluorinated groups. They combine the flexibility and thermal stability of silicones with excellent chemical resistance. FVMQ is particularly suited for applications requiring high performance in environments with extreme temperatures and chemical exposure.

Temperature Range

-60 °C (depending on specific formulations)

+175 °C (depending on specific formulations)

Chemical Compatibility

FVMQ offers excellent resistance to:

Aliphatic and aromatic hydrocarbons

Mineral and synthetic oils and lubricants

Organic solvents (alcohols, light hydrocarbons)

Ozone, UV, and atmospheric aging

Chemical Incompatibility

FVMQ has limitations when exposed to:

Phosphate ester-based hydraulic fluids

Strong acids and concentrated bases

Highly aggressive polar solvents such as ketones and amines

Physical/Mechanical Properties

Excellent thermal stability: Ideal for applications at both high and low temperatures

Good chemical resistance: Particularly to fuels, oils, and modern refrigerants

Optimal resistance to CO2 and hydrogen: Suitable for high-pressure applications

Low compression set: Retains elastic properties even after extended exposure

Good low-temperature flexibility: Exceptional performance in cryogenic environments

Application Examples

Automotive Industry: Seals for fuel systems, engines, and air conditioning (CO2, R744). Applications related to new propulsion technologies

Aerospace and Space Industry: Seals for critical equipment requiring high reliability in extreme environments

Oil and Gas Industry: Sealing for equipment exposed to aggressive fluids and pressure variations

HVAC Applications: Solutions for modern high-performance refrigerants

Electronics: Protection and sealing of components exposed to severe thermal and chemical conditions

FVMQ is positioned as a strategic material for critical environments, combining exceptional resistance to extreme temperatures, aggressive gases, and complex fluids.

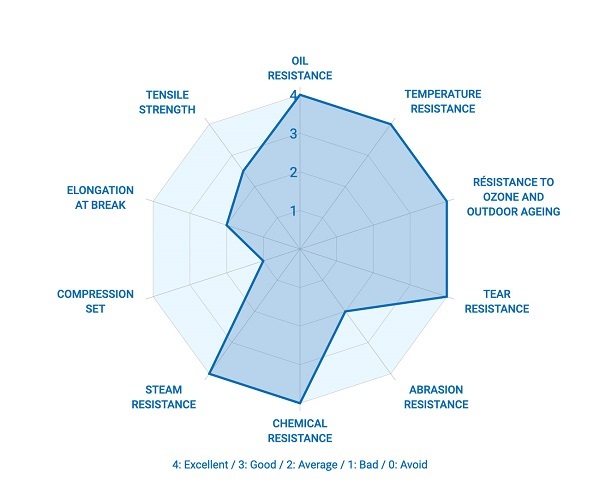

HNBR

Description

HNBR (Hydrogenated Nitrile Butadiene Rubber) is a synthetic elastomer produced through selective hydrogenation of NBR (nitrile-butadiene rubber). This process significantly enhances its thermal, chemical, and mechanical resistance. HNBR is renowned for its robustness and reliability in demanding environments.

Temperature Range

-30 °C (-40 °C for specific formulations)

+150 °C

Chemical Compatibility

HNBR offers excellent resistance to:

Mineral and synthetic oils and lubricants (including oils with additives)

Petroleum-based and water-glycol hydraulic fluids

Light aliphatic and aromatic hydrocarbons

High-pressure gases such as CO2 (R744) and hydrogen

Ozone, UV, and atmospheric agents

Chemical Incompatibility

HNBR has limitations when exposed to:

Heavy aromatic and halogenated hydrocarbons

Aggressive polar solvents such as ketones and esters

Phosphate ester-based fluids

Prolonged exposure to hot water and high-temperature steam

Physical/Mechanical Properties

Excellent thermal and chemical resistance: Suitable for hot oils and aggressive gases

High mechanical strength: Exceptional resistance to tensile forces, abrasion, and tearing

Outstanding RGD (Rapid Gas Decompression) resistance: Ideal for high-pressure environments

Good thermal aging stability: Retains performance over the long term

Customizable for specific formulations: Resistant to CO2, hydrogen, and compliant with fire safety standards such as UL94HB or UL94V0 with special blends

Application Examples

Automotive Industry: Seals for cooling circuits, hydraulic systems, and gearboxes. Applications involving modern fuels and high-pressure fluids

Oil and Gas Industry: Sealing in pipelines and equipment exposed to aggressive fluids, CO2 (R744), and hydrogen

HVAC Applications: Seals for air conditioning systems operating with CO2 or other refrigerants

Industrial Applications: Sealing in complex chemical environments requiring high mechanical strength

Aerospace and Space Industry: Reliable solutions for systems exposed to extreme pressure and temperature variations

HNBR stands out for its versatility and exceptional performance in demanding environments. Its enhanced resistance to pressure, high temperatures, and aggressive gases like CO2 and hydrogen makes it a strategic choice for critical applications.

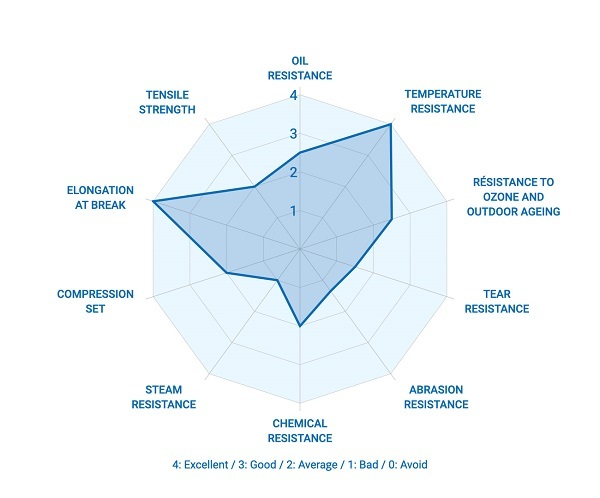

NBR

Description

NBR, or Nitrile Butadiene Rubber, is a synthetic elastomer composed of acrylonitrile and butadiene. It is known for its exceptional resistance to oils, greases, and hydrocarbons, making it a material of choice for many industrial applications requiring strong chemical and mechanical performance.

Temperature Range

-30 °C (down to -40 °C for specific formulations)

+100 °C (up to +120 °C for high-heat-resistant grades)

Chemical Compatibility

NBR exhibits excellent resistance to:

Mineral and synthetic oils, greases, and industrial lubricants

Aliphatic hydrocarbons (e.g., gasoline, diesel)

Petroleum-based hydraulic fluids

Water and moderately aggressive aqueous solutions

Ozone and atmospheric agents (with specific additives) outside automotive applications

Chemical Incompatibility

NBR performs poorly against:

Aromatic and halogenated hydrocarbons (e.g., benzene, toluene, chlorinated solvents)

Phosphate ester-based hydraulic fluids

Ketones, esters, and aggressive polar solvents

Prolonged exposure to ozone and UV without added stabilizers

Physical/Mechanical Properties

Good mechanical strength: Excellent tensile and abrasion resistance

Low gas permeability: Enhanced performance for fluid sealing under pressure

Moderate resistance to compression set: Suitable for both static and dynamic applications

Improved low-temperature flexibility: Dependent on the acrylonitrile content in the composition

Not recommended for high-temperature or highly aggressive environments

Application Examples

Automotive Industry: Seals for oil, fuel, and transmission circuits. Applications in engines and hydraulic systems

Oil and Gas Industry: Sealing for pipelines and equipment exposed to aliphatic hydrocarbons

General Industrial Applications: O-rings, sealing rings, and components for moderately aggressive industrial fluids

HVAC Applications: Seals for traditional refrigerants (excluding aggressive gases like CO2)

Agriculture and Construction: Sealing solutions for hydraulic and pneumatic systems

NBR is a versatile and cost-effective material, offering excellent resistance to oils and hydrocarbons for standard applications. For more demanding environments requiring higher temperature or chemical resistance, other elastomers such as HNBR or FKM may be preferred.

VMQ / MVQ

Description

VMQ (Silicones) are synthetic elastomers known for their excellent thermal stability, low-temperature flexibility, and resistance to aging. They are ideal for applications requiring high performance in environments subjected to extreme temperature variations.

Temperature Range

-60 °C (depending on formulations)

+200 °C (up to +300 °C for certain applications during short-term exposure)

Chemical Compatibility

VMQ offers excellent resistance to:

Ozone, UV, and atmospheric agents (weather aging)

Water and aqueous solutions

Standard refrigerants

Certain diluted acids and bases

Mineral oils (in moderately aggressive environments)

Chemical Incompatibility

VMQ is less effective against:

Aromatic and halogenated hydrocarbons

Aggressive synthetic oils or fluids containing additives

Ketones, esters, and aggressive polar solvents

Prolonged steam exposure and high-pressure hot water

Physical/Mechanical Properties

Excellent thermal stability: Consistent performance across a wide temperature range

Good low-temperature flexibility: Ideal for cryogenic environments or rapid temperature fluctuations

Aging resistance: High durability against UV, ozone, and atmospheric agents

Low mechanical strength: Increased sensitivity to abrasion and tearing compared to other elastomers

Low compression set: Retains elastic properties even after extended exposure

Application Examples

Automotive Industry: Seals for air circuits, cooling systems, and high-temperature sealing systems. Applications for electric motors and components exposed to thermal variations

HVAC Applications: Seals for non-aggressive refrigerants and air conditioning systems

Aerospace and Space Industry: Seals for critical equipment requiring high resistance to extreme temperatures and UV exposure

Food and Medical Industries: Certified seals for food contact and pharmaceutical applications

General Industrial Applications: Solutions for environments requiring high thermal stability and moderate chemical resistance

VMQ is a preferred material for applications where low-temperature flexibility, thermal variation resistance, and environmental durability are essential. However, for chemically aggressive environments or applications with high mechanical stress, other elastomers such as FVMQ or FKM may be more suitable.

MACHINABLE RUBBERS

| Compound N° | Family | Hardness ShA |

Hardness ShD |

Specificity | Certificate | Colour | T°C Min |

T°C Max |

CS % |

CS test |

Tensile |

Elongation at break % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D8501 | AEM | 87 | - | Black | -30 | +150 | - | - | - | 192 | ||

| CR8001 | CR | 81 | - | Black | -40 | +100 | 17 | 24h 100°C | 14,7 | 163 | ||

| C7079 | EPDM | 76 | - | Peroxyde | Black | -53 | +135 | 21,6 | 24h 125°C | 15,8 | 340 | |

| C7080 | EPDM | 77 | - | Peroxydee | FDA EU No 1935/2004 | White | -50 | +135 | 20,3 | 24h 125°C | 6,1 | 380 |

| C8101 | EPDM | 81 | - | KTW D1 KTW D2 |

Black | -40 | +130 | 15 | 24h 70°C | 12 | 150 | |

| C8102 | EPDM | 81 | - | FDA EU No 1935/2004 FDA EU No 2023/2006 |

Blue | -30 | +130 | 15 | 24h 100°C | 9 | 130 | |

| C8103 | EPDM | 81 | - | Detectable | FDA | Blue | -40 | +135 | 17 | 24h 100°C | 9 | 130 |

| C8200 | EPDM | 82 | - | FDA CFR21.177.2600 | White | -45 | +130 | 30 | 24h 100°C | 7 | 160 | |

| C8400 | EPDM | 84 | - | Peroxyde Detectable |

FDA EU No 1935/2004 | Blue | -50 | +135 | 31,5 | 24h 70°C | 5,9 | 186 |

| C9094 | EPDM | 85 | - | Peroxyde | Black | -45 | +130 | 7 | 24h 100°C | 12 | 60 | |

| C9095 | EPDM | 85 | - | FDA | Black | -45 | +130 | 10 | 24h 100°C | 10 | 100 | |

| C9096 | EPDM | 87 | - | Peroxyde | Black | -45 | +135 | 10 | 24h 125°C | 11,7 | 263 | |

| C9097 | EPDM | 87 | - | Sulfur | W270 D1 WRAS BS6920-1:2000 FDA EU No 1935/2004 |

Black | -50 | +135 | 16,3 | 24h 100°C | 15,2 | 249 |

| C9098 | EPDM | 87 | - | Peroxyde | FDA EU No 1935/2004 | White | -40 | +135 | 27,8 | 24h 100°C | 8,4 | 246 |

| G7053 | FKM | 73 | - | Black | -20 | +210 | 13 | 24 | 9 | 250 | ||

| G8124 | FKM | 80 | - | FDA CFR 21.177.2600 | Brown | -20 | +220 | 14 | 24h 175°C | 8 | 150 | |

| G8125 | FKM | 80 | - | FDA EU No 1935/2004 FDA EU No 2023/2006 |

Blue | -17 | +200 | 8 | 24h 100°C | 7 | 160 | |

| G8126 | FKM | 80 | - | Detectable | FDA EU No 1935/2004 FDA EU No 2023/2006 |

Blue | -30 | +200 | 15 | 24h 100°C | 7 | 150 |

| G8128 | FKM | 80 | - | Black | -20 | +220 | 38,6 | 24h 175°C | 11,9 | 123 | ||

| G9115 | FKM | 82 | - | Brown | -20 | +220 | 26 | 24h 175°C | 9 | 200 | ||

| G8127 | FKM | 84 | - | 3A-Sanitary Class I FDA EU No1935/2004 |

White | -25 | +210 | 61,8 | 24h 175°C | 10,5 | 452 | |

| G9116 | FKM | 85 | - | Black | -20 | +210 | 15 | 24h 100°C | 9 | 130 | ||

| G9125 | FKM | 85 | - | RGD | Norsok M-710 | Black | -20 | +220 | 45 | 24h 175°C | 10 | 190 |

| G9126 | FKM | 85 | - | Low temperature | Black | -40 | +200 | 17 | 24h 1OO°C | 6 | 190 | |

| G9129 | FKM | 85 | - | FDA EU No 1935/2004 | Brown | -25 | +220 | 17,7 | 24h 175°C | 10,3 | 207 | |

| G9128 | FKM | 87 | - | Detectable | Blue | -25 | +220 | 17 | 24h 175°C | 10,6 | 82 | |

| G9127 | FKM | 88 | - | RGD | Black | -25 | +215 | 42,2 | 24h 175°C | 13 | 279 | |

| FS0002 | FVMQ | 90 | - | Red | -55 | +230 | 18,1 | 24h 175°C | 6,6 | 160 | ||

| HK7015 | HNBR | 73 | - | Black | -20 | +150 | 22 | 24h 150°C | 22 | 225 | ||

| HK7021 | HNBR | 75 | - | Black | -35 | +150 | 11,4 | 24h 100°C | 23 | 240 | ||

| HK7022 | HNBR | 78 | - | Detectable | FDA EU No 1935/2004 | Blue | -35 | +150 | 29 | 24h 150°C | 8,1 | 270 |

| HK8023 | HNBR | 82 | - | FDA EU No 1935/2004 | Green | -30 | +150 | 40,7 | 24h 150°C | 9,5 | 499 | |

| HK9002 | HNBR | 85 | - | Green | -20 | +150 | 22 | 24h 150°C | 20 | 170 | ||

| HK9004 | HNBR | 85 | - | RGD | Norsok M-710 | Black | -15 | +150 | 30 | 24h 150°C | 17 | 190 |

| HK9005 | HNBR | 88 | - | RGD | Black | -30 | +150 | 23,3 | 24h 150°C | 21,2 | 221 | |

| HK9003 | HNBR | 90 | - | FDA | Black | -20 | +150 | 32 | 24h 100°C | 9 | 220 | |

| HK9006 | HNBR | 95 | - | Black | -20 | +150 | 36,9 | 24h 150°C | 22,7 | 137 | ||

| K6159 | NBR | 73 | - | Black | -30 | +90 | 8 | 24h 100°C | 16 | 190 | ||

| K6160 | NBR | 73 | - | Black | -35 | +110 | 9,9 | 24h 100°C | 14 | 238 | ||

| K8157 | NBR | 80 | - | FDA EU 1935/2004 | Blue | -30 | +100 | 13 | 24h 70°C | 8 | 140 | |

| K8158 | NBR | 80 | - | Low temperature | Black | -50 | +110 | 9 | 24h 100°C | 14 | 130 | |

| K9164 | NBR | 82 | - | Black | -50 | +105 | 13,7 | 24h 100°C | 16,3 | 147 | ||

| K9158 | NBR | 85 | - | Black | -30 | +110 | 6 | 24h 100°C | 17 | 135 | ||

| K9159 | NBR | 85 | - | Blanc | -30 | +110 | 9 | 24h 100°C | 15 | 180 | ||

| K9160 | NBR | 85 | - | Black | -35 | +110 | 12 | 24h 100°C | 15,2 | 226 | ||

| K9163 | NBR | 88 | - | FDA EU No 1935/2004 | White | -30 | +105 | 23,2 | 24h 100°C | 7,8 | 387 | |

| K9165 | NBR | 89 | - | Detectable | FDA EU No 1935/2004 | Blue | -30 | +105 | 49,5 | 24h 100°C | 5,2 | 317 |

| K9162 | NBR | 90 | - | Black | -30 | +110 | 18,5 | 24h 100°C | 18,7 | 82 | ||

| TFEP801 | TFE/P | 83 | - | Black | -5 | +200 | 30 | 24h 150°C | 9 | 110 | ||

| TFEP802 | TFE/P | 87 | - | Black | -10 | +220 | 40 | 24h 175°C | 18,9 | 207 | ||

| TFEP901 | TFE/P | 90 | - | Black | -5 | +200 | 68 | 24h 70°C | 6 | 140 | ||

| HYT541 | TPC-ET | - | 54 | Orange | -30 | +120 | 60 | 24h 70°C | 28 | 300 | ||

| HYT542 | TPC-ET | - | 54 | White | -30 | +120 | 60 | 24h 70°C | 28 | 300 | ||

| F7900 | VMQ | 79 | - | FDA EU No 1935/2004 | Translucent | -60 | +210 | 20 | 24h 175°C | 8,9 | 320 | |

| F8040 | VMQ | 83 | - | FDA EU No 1935/2004 | Red | -60 | +210 | 18,5 | 24h 175°C | 7,4 | 120 | |

| F8038 | VMQ | 84 | - | FDA EU No 1935/2004 | White | -60 | +210 | 18,8 | 24h 100°C | 6,1 | 185 | |

| F8039 | VMQ | 84 | - | FDA EU No 1935/2004 | Blue | -60 | +210 | 33,7 | 24h 100°C | 6,4 | 192 | |

| F8500 | VMQ | 85 | - | Blue | -60 | +200 | 30 | 24h 100°C | 7 | 100 | ||

| F8501 | VMQ | 85 | - | FDA CFR21.177.2600 | Translucent | -60 | +200 | 20 | 24h 175°C | 7 | 210 | |

| F8502 | VMQ | 85 | - | FDA CFR21.177.2600 | White | -60 | +200 | 30 | 24h 100°C | 7 | 100 | |

| F8503 | VMQ | 85 | - | Blue | -60 | +200 | 9 | 24h 100°C | 7 | 120 | ||

| F8504 | VMQ | 85 | - | Translucent | -60 | +200 | 9 | 24h 100°C | 7 | 120 | ||

| F8800 | VMQ | 88 | - | Detectable | FDA EU No 1935/2004 | Blue | -60 | +210 | 26 | 24h 70°C | 6,8 | 122 |

| XK9000 | XNBR | 89 | - | Black | -30 | +110 | 12,9 | 24h 100°C | 21,4 | 144 |

The values are given as a guide only and can evaluate from one mixture to another. We therefore recommend that you carry out your own tests in order to confirm the quality of our materials according to your specific application.

Thermoplastics

PA

Description

Polyamides (PA) are thermoplastic polymers widely used for their excellent mechanical properties, chemical resistance, and durability.

PA6 (Polyamide 6): Derived from caprolactam polymerization, offering a good balance between stiffness and impact resistance.

PA6.6 (Polyamide 6.6): Produced by the condensation of adipic acid and hexamethylene diamine, it is more rigid and heat-resistant than PA6.

PA12 (Polyamide 12): More flexible and moisture-resistant, suitable for applications requiring high flexibility and excellent chemical resistance.

Temperature Range

PA6 and PA6.6:

-40 °C

+100 °C (up to +120 °C for stabilized formulations)

PA12:

-40 °C (down to -60 °C for specific formulations)

+90 °C (up to +110 °C for specialized grades)

Chemical Compatibility

Polyamides offer good resistance to:

Industrial oils and greases

Aliphatic hydrocarbons

Weak acids and diluted bases

Moderate organic solvents

Ozone and atmospheric agents

Chemical Incompatibility

Polyamides are sensitive to:

Strong acids and concentrated bases

Aromatic and halogenated hydrocarbons

Highly aggressive polar solvents (ketones, esters)

Prolonged exposure to hot water (unless specially stabilized formulations are used)

Physical/Mechanical Properties

PA6 and PA6.6:

High mechanical strength: Excellent tensile and abrasion resistance

Superior thermal resistance: Compared to PA12

Low moisture absorption: Suitable for non-immersed applications (stabilization recommended for prolonged moisture exposure)

PA12:

Enhanced flexibility and resilience: Ideal for applications requiring high pliability

Superior chemical resistance: Better performance against moisture and hydrocarbons

Slightly lower mechanical strength: Compared to PA6 and PA6.6

PA6 and PA6.6: Friction rings exposed to abrasion, anti-extrusion rings, washers

PA12: Friction rings in chemically aggressive environments, anti-extrusion rings, washers

Polyamides, in their various forms, offer a unique combination of mechanical, thermal, and chemical performance. The choice between PA6, PA6.6, and PA12 depends on the specific application requirements: rigidity and thermal resistance for PA6.6, flexibility and chemical resistance for PA12.

PEEK

Description

PEEK (Polyetheretherketone) is a high-performance semi-crystalline thermoplastic polymer. It is renowned for its exceptional resistance to high temperatures, chemical stability, and outstanding mechanical properties, making it a preferred material for demanding applications in critical environments.

Temperature Range

-50 °C

+250 °C (up to +300 °C for short-term peak exposure)

Chemical Compatibility

PEEK exhibits exceptional chemical resistance to:

Strong acids and diluted bases

Aromatic, aliphatic, and halogenated hydrocarbons

Mineral and synthetic oils

Organic solvents, ketones, and esters

High-pressure steam, hot water, and high-temperature gases

Chemical Incompatibility

PEEK has very few limitations but may be affected by:

Concentrated acids at very high temperatures (e.g., fuming sulfuric acid)

Gaseous fluorine and molten alkali metals at high temperatures

Physical/Mechanical Properties

Excellent mechanical strength: High rigidity, tensile strength, and low wear

Superior thermal stability: Consistent performance at very high temperatures

Low coefficient of friction: Ideal for tribological applications (moving parts)

Resistance to creep: Retains properties under prolonged loads, even at high temperatures

Exceptional chemical resistance: Nearly universal compatibility with aggressive environments

Chemical inertness and biocompatibility: Suitable for food, medical, and pharmaceutical industries

Application Examples

Oil and Gas Industry: Seals for high-pressure and high-temperature environments

Aerospace and Space Industry: Seals for extreme pressure and temperature conditions

Chemical Industry: Seals and components for equipment handling acids, solvents, and high-pressure fluids

Food Applications: Seals with excellent chemical inertness and thermal resistance

PEEK is a cutting-edge material, ideal for critical applications where thermal, chemical, and mechanical resistance is paramount. Its versatility and performance make it an indispensable choice in the most demanding industries.

HDPE

Description

HDPE (High-Density Polyethylene) is a semi-crystalline thermoplastic polymer derived from the polymerization of ethylene. It is known for its chemical resistance, low density, rigidity, and durability. HDPE is widely used in applications requiring durability, chemical inertness, and lightness.

Temperature Range

-50 °C

+80 °C (up to +100 °C for short periods or specific grades)

Chemical Compatibility

HDPE offers excellent resistance to:

Weak acids and diluted or concentrated bases

Aliphatic hydrocarbons (e.g., gasoline, diesel, mineral oils)

Moderate organic solvents such as alcohols

Water, aqueous solutions, and non-oxidizing chemicals

Ozone and atmospheric aging (with specific stabilized formulations)

Chemical Incompatibility

HDPE is sensitive to:

Aromatic and halogenated hydrocarbons (e.g., benzene, toluene, chlorinated solvents)

Aggressive polar solvents (e.g., ketones, esters)

Concentrated oxidizing acids (e.g., fuming sulfuric acid or concentrated nitric acid)

Prolonged exposure to high temperatures (beyond its maximum range)

Physical/Mechanical Properties

Excellent chemical resistance: Inert against many common chemicals

Good abrasion resistance: Ideal for mechanical applications with moderate wear

Impact resistance: Strong even at low temperatures

Low density: Lightweight and easy to handle

Moderate rigidity: More rigid than low-density polyethylene (LDPE) while retaining some flexibility

Low coefficient of friction: Useful for moving parts

Application Examples

Seals and components for food processing equipment

Seals for linear applications in pneumatic systems

HDPE is a versatile, cost-effective, and high-performing material for applications requiring chemical resistance, lightness, and durability. However, for high-temperature or highly aggressive chemical environments, materials such as PEEK or PTFE may be more suitable.

PFA

Description

PFA (Perfluoroalkoxy) is a thermoplastic fluoropolymer similar to PTFE but offering additional advantages, such as improved processability (injection molding, extrusion) while maintaining exceptional chemical and thermal resistance. PFA is ideal for critical applications requiring a combination of chemical, thermal, and mechanical performance.

Temperature Range

-200 °C

+260 °C (up to +310 °C for certain specific formulations)

Chemical Compatibility

PFA provides near-universal chemical resistance to:

Strong acids (including hydrofluoric acid and concentrated sulfuric acid)

Strong bases and alkaline solutions

Aliphatic, aromatic, and halogenated hydrocarbons

Organic solvents (ketones, esters, etc.)

Aggressive gases

Ozone, UV, and atmospheric agents

Chemical Incompatibility

PFA has very few limitations but can be affected by:

Molten alkali metals and gaseous fluorine at high temperature and pressure

Physical/Mechanical Properties

Exceptional universal chemical resistance: Suitable for the most corrosive environments

Wide temperature range: Ideal for extreme conditions, from cryogenic to high temperatures

Excellent thermal resistance: Consistent performance under prolonged thermal loads

Low coefficient of friction and non-stick properties: Similar to PTFE

Good processability: Injectable and extrudable for complex parts

Moderate mechanical strength: Less rigid than filled PTFE but with improved elasticity

PFA is a top-choice material for demanding applications requiring universal chemical resistance and high thermal performance. Its versatility and excellent mechanical and chemical properties make it indispensable in many industrial sectors.

POM

Description

POM (Polyoxymethylene), also known as acetal or polyacetal, is a semi-crystalline thermoplastic polymer. It is characterized by high stiffness, excellent mechanical strength, and a low coefficient of friction. These features make it a preferred material for applications requiring precision, durability, and tribological performance.

Temperature Range

-40 °C

+100 °C (up to +140 °C for specific grades and short-term exposure)

Chemical Compatibility

POM offers excellent resistance to:

Mineral oils and industrial greases

Aliphatic and aromatic hydrocarbons

Aqueous solutions, weak acids, and diluted bases

Moderate organic solvents (alcohols, ethers)

Ozone and atmospheric agents

Chemical Incompatibility

POM is sensitive to:

Strong acids (e.g., concentrated sulfuric acid)

Strong bases (e.g., concentrated sodium hydroxide or potassium hydroxide)

Highly polar solvents like ketones, esters, and amines

Gaseous chlorine and powerful oxidizing agents

Physical/Mechanical Properties

Excellent rigidity and mechanical strength: Ideal for applications requiring high precision and wear resistance

Low coefficient of friction: Outstanding tribological performance, reducing wear in moving parts

Good dimensional stability: Consistent properties under varying temperatures and loads

Moderate chemical resistance: Suitable for most oils and solvents but limited against strong acids and concentrated bases

Moisture resistance: Low water absorption, maintaining performance in humid environments

Application Examples

Sliding rings and wear parts

Anti-extrusion rings

Guide rings

POM is a versatile material, combining stiffness, precision, and durability. It is particularly suited for mechanical and tribological applications where dimensional stability and low wear are critical. However, for chemically aggressive environments or high-temperature conditions, alternatives like PEEK or PTFE may be more appropriate.

PK

Description

PK (Polyketone) is a semi-crystalline thermoplastic polymer composed of a chain of carbon monoxide and olefins. This material is valued for its excellent mechanical and chemical resistance and its low environmental impact, as it is produced using carbon monoxide, making it a sustainable choice for various industrial applications.

Temperature Range

-40 °C

+120 °C (up to +150 °C for certain stabilized formulations)

Chemical Compatibility

PK offers excellent resistance to:

Industrial oils and lubricants

Aliphatic hydrocarbons

Light organic solvents (alcohols, ethers)

Aqueous solutions, weak acids, and diluted bases

Ozone, UV, and atmospheric agents

Chemical Incompatibility

PK is sensitive to:

Aromatic and halogenated hydrocarbons

Strong acids and concentrated bases

Aggressive polar solvents (ketones, esters, amines)

Physical/Mechanical Properties

Excellent mechanical strength: High modulus of rigidity and good tensile strength

High abrasion resistance: Ideal for tribological applications or parts subject to wear

High dimensional stability: Consistent performance even in high-humidity environments

Moderate to high chemical resistance: Suitable for many common industrial environments

Ease of processing: Injection molding or extrusion for complex parts

Eco-friendly: Low carbon footprint due to its production using carbon monoxide

Application Examples

Friction rings subjected to high pressures

Guide rings

Back-up rings

PK combines sustainability, mechanical strength, and chemical resistance, offering a more eco-friendly alternative to other polymers. With its robustness and wear resistance, it is an excellent choice for demanding industrial applications.

TPU (Polyurethanes)

Description

TPUs (Thermoplastic Polyurethanes) are thermoplastic elastomers characterized by their high elasticity, excellent mechanical and chemical resistance, and durability. They consist of rigid and flexible segments, offering a unique combination of properties, suitable for demanding industrial applications.

Temperature

-40 °C (up to -60 °C for some specific grades)

+90 °C (up to +120 °C for specific formulations)

Chemical compatibility

TPUs offer good resistance to:

Mineral oils and industrial greases.

Aliphatic hydrocarbons (gasoline, diesel).

Petroleum-based hydraulic fluids.

Diluted aqueous solutions and some weak acids.

Ozone, UV, and atmospheric aging.

Chemical incompatibility

TPUs are less suitable for:

Aromatic and halogenated hydrocarbons.

Ester phosphate-based hydraulic fluids.

Highly polar solvents such as ketones, esters or amines.

Hot water and prolonged steam at high temperatures.

Physical/mechanical properties

Excellent abrasion resistance: ideal for environments subject to high mechanical stress.

High elasticity: suitable for applications requiring flexibility and resilience.

Good resistance to aging: long-term resistance to varied climatic conditions.

Moderate chemical resistance: reliable performance with light oils and hydrocarbons.

Rigidity and strength: properties adjustable according to formulations to meet specific needs.

Application examples

Automotive industry: Seals subject to vibration and abrasion.

General industrial applications: Seals and gaskets for mechanical equipment exposed to high stress.

Food industry: Applications certified for food contact, such as seals for processing equipment.

Agriculture and construction: Solutions for equipment subject to abrasion and exposure to oils and hydrocarbons.

Aerospace: Seals requiring high mechanical performance in varied environments.

TPUs combine flexibility, robustness and mechanical resistance, making them indispensable for many demanding applications. Their use is particularly recommended in environments requiring excellent resistance to abrasion and oils. However, for chemically very aggressive or high temperature environments, other materials such as FKM or HNBR may be more appropriate.

Injectable Polyurethanes (our standards)

| Compound N° | Family | Hardness ShA |

Hardness ShD |

Colour | T°C Min |

T°C Max |

Compression set % |

Compression set test |

Tensile strength MPa |

Elongation at break % |

|---|---|---|---|---|---|---|---|---|---|---|

| PU90000 | TPU | 93 | 41 | Blue | -30 | +90 | 45 | 24h 70°C | 55 | 600 |

| PUHT900 | TPU | 91 | - | Cream | -30 | +110 | 45 | 24h 100°C | 45 | 600 |

| PU95000 | TPU | 96 | 48 | Blue | -30 | +90 | 45 | 24h 70°C | 50 | 550 |

| PUHT950 | TPU | 96 | - | Cream | -30 | +110 | 50 | 24h 100°C | 50 | 550 |

| PU98000 | TPU | 98 | 55 | Blue | -30 | +90 | 45 | 24h 70°C | 45 | 500 |

The values are given as a guide only and can evaluate from one mixture to another. We therefore recommend that you carry out your own tests in order to confirm the quality of our materials according to your specific application.

Machinable Polyurethanes (our standards)

| Compound N° | Family | Hardness ShA |

Hardness ShD |

Specificity | Certificate | Colour | T°C Min |

T°C Max |

CS % |

CS conditions |

Tensile MPa |

Elongation % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PU95021 | TPU | 95 | 48 | FDA 10/2011EC | Red | -20 | 115 | 33 | 24h 100°C | 50 | 350 | |

| PU950028 | TPU | 95 | 48 | Blue | -20 | 115 | 33 | 24h 100°C | 50 | 350 | ||

| PU930015 | TPU | 93 | 40 | Detectable | EU N°1935/2004 EU N°2023/2006 |

Dark blue | -40 | 90 | 32 | 24h 70°C | 42 | 350 |

| PU900010 | TPU | 90 | - | Fuel resistant | Light yellow | -20 | 110 | 27 | 24h 70°C | 50 | 380 | |

| PU950029 | TPU | 95 | 46 | Detectable | EU N°1935/2004 EU N°2023/2006 |

Light blue | -20 | 90 | 38 | 24h 100°C | 45 | 340 |

| PU550000 | TPU | - | 55 | Hydrolyse | Yellow | -20 | 115 | 35 | 24h 100°C | 45 | 310 | |

| PU960000 | TPU | 96 | 50 | Hydrolyse | FDA CFR 21-177.2600 | Red | -37 | 110 | 35 | 24h 100°C | 45 | 450 |

| PU570000 | TPU | - | 57 | Hydrolyse | Yellow | -30 | 110 | 35 | 24h 100°C | 45 | 350 | |

| PU700000 | TPU | - | 70 | Black | -20 | 110 | 50 | 150 | ||||

| PU940010 | TPU | 94 | 49 | Blue | -55 | 110 | 30 | 24h 100°C | 45 | 400 | ||

| PU570010 | TPU | - | 57 | Blue | -55 | 110 | 45 | 24h 70°C | 45 | 350 | ||

| PU960010 | TPU | 96 | 48 | Lubricated | Black | -20 | 110 | 35 | 24h 100°C | 45 | 350 | |

| PU550010 | TPU | - | 55 | Low friction | Black | -20 | 110 | 35 | 24h 100°C | 45 | 330 | |

| PU93016 | TPU | 93 | 47 | Green | -30 | 110 | 33 | 24h 100°C | 50 | 450 |

The values are given as a guide only and can evaluate from one mixture to another. We therefore recommend that you carry out your own tests in order to confirm the quality of our materials according to your specific application.

PTFE

Description

PTFE (Polytetrafluoroethylene): Fluorinated polymer known for its exceptional chemical resistance, low coefficient of friction and wide operating temperature range.

Modified PTFE: Variant of pure PTFE with improved mechanical properties and better creep resistance due to chemical modifications.

Filled PTFE: PTFE reinforced with fillers (glass, carbon, graphite, bronze, etc.) to optimize its mechanical, thermal or tribological properties depending on the application needs.

Temperature

-200 °C

+260 °C (varies according to fillers for modified and filled PTFE)

Chemical compatibility

PTFE, in its different variants, is extremely resistant to:

Most aggressive chemicals (acids, bases, organic solvents, etc.).

Aliphatic, aromatic and halogenated hydrocarbons.

Industrial oils and lubricants.

Refrigerants such as CO2 (R744) and hydrogen.

High temperature steam and high pressure gas.

Chemical incompatibility

PTFE is little affected by chemical environments, but may be sensitive to:

Molten alkali metals at high temperatures.

Fluorine gas at high pressure and temperature.

Physical/mechanical properties

Pure PTFE:

Exceptional resistance to chemicals and heat.

Low coefficient of friction and non-adhesion.

Low mechanical strength and tendency to creep under high load.

Modified PTFE:

Improved resistance to creep and permanent deformation.

Slightly increased mechanical properties while maintaining chemical and thermal advantages.

Filled PTFE (depending on fillers):

Glass: Increases rigidity and reduces creep, with excellent thermal resistance.

Carbon/Graphite: Improves thermal conductivity and anti-wear properties.

Bronze: Increases compressive strength and improves thermal conductivity.

Other fillers (MoS₂, ceramic, metal oxides, ekonol, ...): Optimize tribological performance in specific applications.

Application examples

Automotive industry: Seals for air conditioning systems, oil circuits and high-pressure components.

Chemical industry: Static and dynamic seals for equipment handling aggressive fluids.

Energy and oil: Sealing in environments subject to extreme pressures and temperatures.

Aerospace: Solutions for critical systems requiring maximum reliability.

General industrial applications: Anti-wear parts and slides for equipment subject to high mechanical stress.

PTFE, whether pure, modified or filled, offers an essential solution for applications requiring maximum chemical and thermal resistance. The modified and filled variants allow their mechanical and tribological performances to be adjusted according to specific requirements.

| Compound N° | Type | Certificate | Colour | Hardness ShD |

T°C Min |

T°C Max |

Tensile MPa |

Elong. % |

Water absorpt. |

Stat. Frict. coef. |

Dyn. Frict. coef. |

Wear |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DB002 | PTFE 60% Bronze |

Brown | 65 | -200 | +260 | 17 | 150 | 0,03 | 0,16 0,18 |

0,16 0,18 |

10 15 |

|

| DB003 | PTFE 60% Bronze |

Brown | 67 | -200 | +260 | 12 | 120 | 0,00 | 0,18 | 0,14 | - | |

| DB004 | PTFE 40% Bronze |

Brown | 65 | -200 | +260 | 15 | 180 | 0,03 | 0,16 0,18 |

0,14 0,16 |

15 20 |

|

| DBM001 | PTFE 40% Bronze + 5% MoS2 |

Brown | 65 | -200 | +260 | 18 | 180 | 0,03 | 0,15 0,17 |

0,12 0,14 |

15 20 |

|

| DC004 | PTFE 25% Carbon |

Black | 62 | -200 | +260 | 13 | 60 | 0,03 | 0,14 0,16 |

0,12 0,14 |

35 | |

| DC005 | PTFE 35% Carbon |

Black | 63 | -200 | +260 | 15 | 40 | 0,05 | 0,14 0,16 |

0,13 0,15 |

30 | |

| DC006 | PTFE 25% Carbon soft |

Norsok M710 | Black | 60 | -200 | +260 | 15 | 100 | 0,03 | 0,14 0,16 |

0,12 0,14 |

150 |

| DCC01 | PTFE 10% Coke Carbon |

Black | 62 | -200 | +260 | 20 | 200 | 0,00 | 0,14 0,15 |

0,10 0,11 |

120 | |

| DCF01 | PTFE 10% Carbon fiber |

Black | 60 | -200 | +260 | 20 | 200 | 0,03 | 0,25 0,30 |

0,18 0,27 |

115 | |

| DCF02 | PTFE 2% Special conductive carbon fiber |

Black | 54 | -200 | +260 | 22 | 250 | 0,01 | 0,08 0,10 |

0,06 0,08 |

20000 25000 |

|

| DCG006 | PTFE 23% Carbon + 2% Graphite |

Black | 62 | -200 | +260 | 13 | 60 | 0,03 | 0,13 0,15 |

0,11 0,13 |

34 | |

| DG001 | PTFE 15% Graphite |

Black | 55 | -200 | +260 | 14 | 180 | 0,05 | 0,12 0,14 |

0,10 0,12 |

2000 2500 |

|

| DG002 | PTFE 10% Graphite |

Black | 54 | -200 | +260 | 18 | 200 | 0,05 | 0,12 0,14 |

0,10 0,12 |

2000 2500 |

|

| DI001 | PTFE 50% Stainless steel |

Grey | 65 | -200 | +260 | 15 | 130 | 0,03 | 0,16 0,18 |

0,13 0,15 |

30 40 |

|

| DM001 | Virgin PTFE | USP VI | White | 54 | -200 | +260 | 25 | 280 | 0,01 | 0,08 0,10 |

0,06 0,08 |

20000 25000 |

| DM002 | PTFE 5% MoS2 |

Azure blue | 55 | -200 | +260 | 25 | 250 | 0,03 | 0,08 0,10 |

0,06 0,08 |

2000 2200 |

|

| DM003 | PTFE 3% MoS2 |

Azure blue | 55 | -200 | +260 | 25 | 250 | 0,03 | 0,08 0,10 |

0,06 0,08 |

2000 2200 |

|

| DM004 | PTFE 0,2% MoS2 |

Azure blue | 55 | -200 | +260 | 25 | 250 | 0,03 | 0,08 0,10 |

0,06 0,08 |

20000 22000 |

|

| DM005 | PTFE 0,1% MoS2 |

Azure blue | 55 | -200 | +260 | 25 | 250 | 0,03 | 0,08 0,10 |

0,06 0,08 |

20000 22000 |

|

| DMXD01 | PTFE Détectable | Blue | 35 | -200 | +260 | 25 | 25 | 0,03 | 0,16 0,18 |

0,13 0,15 |

30 40 |

|

| DP0014 | Modified PTFE Antistatic |

White | - | -200 | +260 | - | - | - | - | - | - | |

| DP0015 | Virgin PTFE Antistatic |

White | - | -200 | +260 | - | - | - | - | - | - | |

| DP008 | Virgin PTFE | FDA | White | 54-60 | -200 | +260 | 20-30 | 200-350 | 0,00 | 0,08 | 0,06 | - |

| DP009 | Virgin PTFE Standard Grade |

White | 54 | -200 | +260 | 20 | 200 | 0,01 | 0,08 0,10 |

0,06 0,08 |

20000 25000 |

|

| DP010 | Modified PTFE - Premium Grade | Norsok M710 API 6A (ISO10423) |

White | 54 | -200 | +260 | 30 | 450 | 0,01 | 0,08-0,10 | 0,06 0,08 |

20000 25000 |

| DP012 | Modified PTFE - Standard Grade | White | 54 | -200 | +260 | 28 | 400 | 0,01 | 0,08 0,10 |

0,06 0,08 |

20000 25000 |

|

| DP013 | Virgin PTFE - Premium Grade |

Norsok M710 API 6A (ISO10423) |

White | 54 | -200 | +260 | 25 | 280 | 0,01 | 0,08 0,10 |

0,06 0,08 |

20000 25000 |

| DPA01 | PTFE + Aromatic Polyester |

FDA | Brown | 60 | -200 | +260 | 15 | 180 | 0,01 | 0,10 0,12 |

0,12 0,14 |

4 |

| DPA02 | PTFE + Brown Aromatic Polyester |

FDA | Brown | 54 | -200 | +260 | 15 | 180 | 0,01 | 0,12 0,14 |

0,10 0,12 |

4 |

| DPC001 | Modified PTFE + 25% Carbon |

Black | 60 | -200 | +260 | 13 | 40 | 0,03 | 0,12 0,15 |

0,11 0,13 |

150 | |

| DPEEK01 | PTFE + PEEK | Brown - Beige | 65 | -200 | +260 | 13 | 35 | 0,02 | 0,13 0,15 |

0,09 0,12 |

10000 15000 |

|

| DPV001 | Modified PTFE 25% Glass |

- | - | -200 | +260 | - | - | - | - | - | - | |

| DV001 | PTFE 15% Glass + 5% MoS2 |

Blue - Grey | 58 | -200 | +260 | 18 | 200 | 0,05 | 0,12 0,25 |

0,10 0,12 |

15 25 |

|

| DV002 | PTFE 15% Glass |

White cream | 58 | -200 | +260 | 18 | 200 | 0,03 | 0,18 0,20 |

0,11 0,13 |

15 25 |

|

| DV003 | PTFE 40% Glass |

White cream | 63 | -200 | +260 | 10 | 100 | 0,03 | 0,17 0,20 |

0,15 0,17 |

15 25 |

|

| DV004 | PTFE 25% Glass |

White cream | 60 | -200 | +260 | 13 | 180 | 0,03 | 0,17 0,20 |

0,15 0,17 |

15 25 |

|

| DVCG001 | PTFE 10% Glass + 15% Carbon + 2% Graphite |

Black | 60 | -200 | +260 | 11 | 60 | 0,05 | 0,12 0,25 |

0,10/ 0,12 |

25 40 |

|

| DVG001 | PTFE 20% Glass + 5% Graphite |

Black | 58 | -200 | +260 | 16 | 180 | 0,05 | 0,12 0,25 |

0,10/ 0,12 |

20 25 |

|

| DX | PTFE "Gel Blue" | Blue | 60 | -200 | +260 | 13 | 180 | 0,03 | 0,17 0,20 |

0,15 0,17 |

15 25 |

The values are given as a guide only and can evaluate from one mixture to another. We therefore recommend that you carry out your own tests in order to confirm the quality of our materials according to your specific application.

AEROSPACE MATERIALS

CR

| Compound N° | Base | Hardness DIDC |

Codification | Correspondence | Media | Temperature | |||

|---|---|---|---|---|---|---|---|---|---|

| National | European | Definition | Standard | in extended service | in limited service | ||||

| CR5001 | CR | 60 | 31B6 | NF L 17-131 | --- | Atmospheric agents Petroleum lubricants – turbine oil – piston engine oil |

AIR 3512 AIR 3560 |

-40°C / +100°C | -40°C / +120°C |

| CR6009 | CR | 70 | 31B7 | ||||||

| CR8002 | CR | 80 | 31B8 | ||||||

EPDM

| Compound N° | Base | Hardness DIDC |

Codification | Correspondence | Media | Temperature | |||

|---|---|---|---|---|---|---|---|---|---|

| National | European | Definition | Standard | in extended service | in limited service | ||||

| C8104 | EPDM | 80 | 41B8 | NF L 17-241 | --- | Hydraulic fluid Phosphoric ester type |

--- | -55°C / +100°C | -55°C / +150°C |

| C4107 | EPDM | 60 | 42B6 | L 17-242-2 | EN 2429 | Atmospheric agents Hot air |

--- | -55°C / +125°C | -55°C / +160°C |

| C8105 | EPDM | 80 | 44B8 | NF L 17-144 | --- | Hydraulic fluid Phosphoric ester type Environment requiring the use of colored matter |

--- | -55°C / +100°C | -55°C / +150°C |

FKM

| Compound N° | Base | Hardness DIDC |

Codification | Correspondence | Media | Temperature | |||

|---|---|---|---|---|---|---|---|---|---|

| National | European | Definition | Standard | in extended service | in limited service | ||||

| G6131 | FKM | 70 | 60C7 | NF L 17-260 | --- | Petroleum fluids, hydraulic fluids, lubricants, fuels, etc. Diester lubricants |

AIR 3514 | -20°C / +200°C | -20°C / +260°C |

| G9130 | FKM | 90 | 60C9 | --- | |||||

| G8032 | FKM | 80 | 64C8 | NF L 17-164 | --- | Petroleum fluids, hydraulic fluids, lubricants, fuels, etc. Diester lubricants |

AIR 3514 | -20°C / +230°C | -20°C / +260°C |

FVMQ

| Compound N° | Base | Hardness DIDC |

Codification | Correspondence | Media | Temperature | |||

|---|---|---|---|---|---|---|---|---|---|

| National | European | Definition | Standard | in extended service | in limited srvice | ||||

| FS4001 | FVMQ | 60 | 61D6 | NF L 17-261 | --- | Petroleum fluids, hydraulic fluids, lubricants, fuels, etc. | --- | -55°C / +180°C | -55°C / +2000°C |

| FS6001 | FVMQ | 70 | 61D7 | --- | |||||

| FS8001 | FVMQ | 80 | 61D8 | --- | |||||

| FS4002 | FVMQ | 60 | 63D6 | NF L 17-163 | --- | Petroleum fluids, hydraulic fluids, lubricants, fuels, etc. Good tear resistance |

--- | -55°C / +150°C | -55°C / +200°C |

NBR

| Compound N° | Base | Hardness DIDC |

Codification | Correspondence | Media | Temperature | |||

|---|---|---|---|---|---|---|---|---|---|

| National | European | Definition | Standard | in extended service | in limited service | ||||

| K3010 | NBR | 50 | 20A5 | NF L 17-120 | --- | Mineral-based and synthetic hydrocarbon-based hydraulic fluid (MIL-H-83282) | DCSEA 415 | -30°C / +120°C | -30°C / +140°C |

| K4024 | NBR | 60 | 20A6 | ||||||

| K6167 | NBR | 70 | 20A7 | ||||||

| K8159 | NBR | 80 | 20A8 | ||||||

| K3011 | NBR | 50 | 20B5 | -50°C / +100°C | -50°C / +120°C | ||||

| K4025 | NBR | 60 | 20B6 | ||||||

| K6168 | NBR | 70 | 20B7 | ||||||

| K8160 | NBR | 80 | 20B8 | ||||||

| K4026 | NBR | 60 | 21A6 | NF L 17-121 | --- | Petroleum fuels Diester lubricants – Gasoline 100-130 – JP.1 – JP.4 – Synthetic turbine oil |

DCSEA 118 DCSEA 134 AIR 3407 AIR 3514 |

20°C / +120°C | -20°C / +140°C |

| K6169 | NBR | 70 | 21A7 | ||||||

| K4027 | NBR | 60 | 21B6 | Petroleum fuels – Gasoline 100-130 – JP.1 – JP.4 |

DCSEA 118 DCSEA 134 AIR 3407 |

-40°C / +100°C | -40°C / +120°C | ||

| K6170 | NBR | 70 | 23B7 | NF L 17-123 | --- | Diester lubricant | AIR 3514 | -50°C / +120°C | -50°C / +140°C |

| K6171 | NBR | 70 | 24B7 | NF L 17-124 | --- | Mineral-based and synthetic hydrocarbon-based hydraulic fluid (MIL-H-83282) | DCSEA 415 | -50°C / +120°C | -50°C / +140°C |

VMQ

| Compound N° | Base | Hardness DIDC |

Codification | Correspondence | Media | Temperature | |||

|---|---|---|---|---|---|---|---|---|---|

| National | European | Definition | Standard | in extended service | in limited service | ||||

| F3019 | VMQ | 50 | 50D5 | L 17-250-2 | EN 2259 | Atmospheric agents Hot air Dielectric uses |

--- | -55°C / +225°C | -55°C / +260°C |

| F4026 | VMQ | 60 | 50D6 | L 17-250-3 | EN 2260 | ||||

| F6050 | VMQ | 70 | 50D7 | L 17-250-4 | EN 2261 | ||||

| F3020 | VMQ | 50 | 52D5 | L 17-250-6 | EN 2262 | Atmospheric agents Hot air Good tear resistance |

--- | -55°C / +200°C | -55°C / +225°C |

| F3021 | VMQ | 50 | 53D5 | NF L 17-153 | --- | Atmospheric agents Hot air Good resistance to flame propagation |

--- | -70°C / +200°C | -70°C / +225°C |